Description

Description

Ultimate Nipper is a nipper that specializes in gate cutting and pursues the "ultimate cut". Ultra thin single edged structure brings excellent performance with less work time!

When trying to slice and cut the 3mm runner, the blade will move freely and smoothly without any noise. “Shave & Cut” structure allows a smooth cut surface as if it is cut off by a design knife and it minimizes plastic whitening. Compared to a standard nipper, the section that is cut has a clean surface which is beneficial to those who want to finish the plastic models without painting.

For people who paint plastic models, this is the best nipper to use because when they cut along the edge, it leaves no remains of the gate. It leaves with a clean cut section. This shortens the time spent on filing the gate.

When cutting small parts, it will not fly away. It will decrease the amount of time spent searching for the fly away parts.

Ultimate nipper not only does it save time but also require less work. To cut off a 3mm plastic, the Ultimate nipper only requires a force of 2kg when a normal nipper requires a force of 3.5-10kg.

Cutting Blade and “Single-Edged Structure” striving for clean cutting.

The ultimate nipper consists of the cutting blade and the single edged structure which creates super clean cutting surface. The essence of Ultimate Nipper is the thin and sharp like knife, “Cutting Edge”. Ultra-thin “cutting edge” is created one by one by a well experienced craftsmanship in Tsubame-Sanjo, Niigata prefecture, Japan.

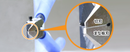

Single Edged Structure is where one blade is the “Cutting Edge” and the other blade is the “Cutting board Edge”, like a knife and a cutting board. Only one blade has an edge (cutting blade), so it is called “Single Edged”. The cutting board edge supports an object firmly while the gripping force changes to move the cutting edge smoothly. The cutting board edge protrudes a bit from the cutting edge. It plays an important role to cut off accurately and avoid deformities. As a result, there will remain a very small part of the gate. This is because “accurately cutting” is prioritized than having a flat cut section.

Any nipper will become loose as it gets old. When the cutting edge and the cutting board edge are not aligned, it will result in an unclean cut and possible chipping and breaking of the blades. In order to avoid this situation, the cutting edge board has a wider range so that when it deteriorates and gets loose, it will still allow for proper function.

Specifications

Material: Special tool steels (Kobe Steel, Ltd)

Length: about 120mm

Weight: about 60g

Hardness of the edge: More than HRC58

Cutting capability: Cut plastic only (polystyrene, polypropylene, acrylonitrile-butadiene-styrene, and PE plastic) .

Cutting capacity: Limited under 3mm

*Transparent and semi-transparent PS resin is difficult to cut, so it is limited to under 1mm.

Features:

- Single- edged structure

- Blade stopper to prevent chipping

- Pin for preventing opening excessively

- Spring structure

- Soft grips

- Original nipper cap is included

Product Updates

- Pin for preventing opening excessively: The pin has been changed from metal to resin. The pin has a tapered shape, so, it prevents the pin from being pushed in further by a force.

- Blade stopper to prevent chipping/breakage of blades: To make a clean cut, the cutting edge has to touch the cutting board edge firmly. There is a tiny gap between the stopper and nipper so they do not touch each other with light force. The stopper works just before the blades break by closing it with a strong force.

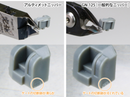

- Wider tips: The Ultimate Nippers had thin tips but were intentionally adjusted to have wider tips. We had several customers who broke the tips from being too thin, so we redesigned the tip shape to be wider to prevent them from chipping.

- Current Spec/Previous Spec: We are doing our best to improve our products everyday. The spec is subject to change without notice. Your understanding is greatly appreciated

[!]Notes

- The nipper is delicate because the goal is to achieve a clean cut. If the nipper is used incorrectly, it may result in chipping and/or breaking

- To prevent injuries, please use it with caution as stated below

- It has the ability to cut items with very light force, so please do not grip it excessively.

- The blade is thinner towards the tip which can be chipped easily. In order to prevent chipping, please cut objects using the middle of the blade.

- Please do not twist blades during and after cutting runners. If twisted, it could cause the blade to break.

- Do not cut items that are longer than the blades. One point of the blade takes a lot of force which could cause chipping and or breaking

- Please do not cut thicker plastic, or materials that are not compatible with use. (Examples: metal, resin, paper, etc.)

- Please do not use for cutting plastic board, tag, parts, and dowel holes.

- Remove remains during and after using a toothbrush. Cutting with remains may cause breaking due to the remains being too heavy for the blades. Especially if the remains are at the bottom of the blades, the blades could easily be misaligned

- Do not touch the tip of the cutting edge. The cutting edge is sharp which could cause injuries.

- Sebum could cause rusting. Please wipe off finger prints on the metal parts if touched and apply anti-rust oil on them.

- Humidity also causes rusting, so please oil frequently during humid seasons

- Please oil the joint section regularly to prevent the section from getting loose to avoid the decline of the cutting quality.

- For your safety, please wear safety glasses. Fragments might fly during use. Please check the safety of your surroundings and that no fragile items are around before use

- Please keep children out of reach.

- Put the included nipper cap on after use with caution

See Related Product: GodHand Nipper Cap with Snap Fast

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.